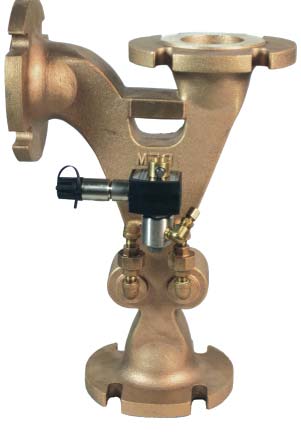

PEM W150 CAST BRONZE 1 1/2” WATER SWITCHES

PEM WATER SWITCHES, BASIC INFORMATION:

PEM Water Switches or Flow Diverters are intended to switch the flow of a water supply within a fraction of a second from

one outlet to another. Within these devices, water pressure from the supply pipe is converted into flow velocity, then

reconverted into a lower outlet pressure. The function can be described as following:

The water inflow from the supply pipe is directed at the junction of 2 branches of a Y-Tee. As the inflowing water entrains ambient

atmospheric pressure, replenishing atmospheric pressure from the snorkel is drawn evenly through 2 transverse ports

at the base of the Y. By opening or closing one of these two ports, a so called 'COANDA EFFECT' takes place, which

bends the stream of the incoming water toward the Y leg at the side that has its port closed. By controlling the atmospheric

pressure taken in by these ports from the snorkel with a low voltage solenoid valve, the COANDA EFFECT can be directed

from one branch of the Y outlet to the other, in effect switching the flow of water from the one outlet to the other.

The very nature of the device does not permit valving or excessive back pressure of the outlets. The flow usually is

controlled before entering the device or by the use of a by-pass valve on the outflow side of the diverter. Direct connection of a

spray jet to the vertical outlet is recommended only for nozzles insensitive to turbulent inflow.

Nozzles requiring a non turbulent inflow require a pipe nipple of appr. 6 times pipe size in length with a flowstraightener at the

inflow of the nozzle, or a vertical ball type check valve under the jet or at the water switch outflow.

If the snorkel terminates below waterlevel, the unit does not work. Normally a larger spray jet or several smaller spray jets can

be operated at one time with the vertical outflow port, with the horizontal outflow port serving as exhaust, however this port ( of

same full flow pipe size ) can also be equipped with a spray jet to provide an alternating spray effect, however it has a lesser

output pressure. For remote installation of the water switches, the snorkel air pressure intake (extended with suitable tubing

must be at a level above the water-level of the pool/pond in which the jets are used to prevent back drainage when system is

not operating.

In the selection of spray jets, waterlevel independent and low back pressure jets or nozzles can be used with suitable pipe

fittings, such as water switch performance tested PEM jets. Waterlevel dependent aerated jets and cascade jets should not

be used. Never use standard nozzle performances as of normal pipe supply application for use with water switches, consult

manufacturers performance data of water switch inflow requirements for a variety of nozzles and jet. It must be realized, that

these water switches or flow diverters require full inflow and pressure at all times, even if the spray effect is not working

while the supply is being exhausted.

What to watch for:

Electric controlled water switches have no internal moving parts other than in the attached solenoid 3 way valve,which has no

flow through other than to control actual air pressure to the two activating ports in the water switch. The heavy duty, water

duty, all stainless steel electric solenoid 3 way valve used with the water switch requires a constant operating voltage of not more

than plus/minus (+/-) 5% of rated voltage to operate for the maximum life expectancy of appr. several million operating cycles.

Too much voltage = the coil will bust, too little voltage = the valve is oscillating (machine gunning) causing internal parts to

destruct.The solenoid valve coils are terminated into a submersible plug in connection for the electrical supply cable. A PEM

low voltage testing device permits accurate reading of operating voltage at valve. Manual controlled water switches with

built in air pressure valve are connected with 2 tubes to the water switch, transferring the air pressure intake from one

port to the other within the water switch while depressed.

The water switches require to be operated in clean water, algae free, with suction straining to suit the jet, nozzle or flow

straightener on the outflow side. Maximum suggested suction strainer orifices for water switch without jets or nozzles are: 1"

Inlet Size = 0.125"/3mm, 1 1/2" Inlet Size = 0.187"/5mm, 2" & 3" Inlet Size= 0.250"/6mm.

Long string algae and hair can get caught within the water switch junction, to remove: Remove water switch and clean, usually

caused by missing or to small suction strainers with too great suction flow velocity!

For multiple installations i the water switches to be connected to the water supply with bayonet plug-in quick disconnects and

electrical cable plug-in disconnects to permit servicing of individual units without interfering with the system. Properly

installed with proper supplies, under normal working conditions, the water switches do not require maintenance other than

critical observation - just in case. If the snorkel(s) ever get immersed for whatever reason, dirt can get into the solenoid

valve, requiring it to be cleaned. In area with water flies, the snorkel requires a #1.15 insect screen To clean the solenoid

valve, shut off electrical power to the entire pool, remove solenoid valve from water switch ( 4 small bolts & nuts), open large hex

nut at bottom of valve body - be careful it is spring loaded. Do not lose the internal spring. Remove plunger, clean valve with

compressed air, re-assemble all parts and re-install on same side of water switch body. Operating voltage below specified, might

cause rapid self energizing (machine gunning) of solenoid valve piston, will deform same and stop valve from operating. Use

PEM 003 Voltage tester to assure specified operating voltage, which valve is energized. Supply voltage at supply tranformer or

power supply might not be same as operating voltage at water switch. When replacing water switches by other manufacturers

using 2 solenoid valves at waterswitch, install a Ratchet Relay at power supply, to allow the PEM Water Switches with 3 way

solenoid valves to work on second impulse. For winterizing in cold climates: Disconnect the Water Switches (with quick

disconnects) and store frost free.